Stiatic Capacity

Unless there is relative motion between the rings of a ball bearing,the depressions of the balls into the races will gradually enlarge,and permanent indentations will remain worm gear reducer .The static capacity is ordinarily defined as the maximum allowable static worm gear reducer load that does not impair the runing characteristics of the bearing to make it unusable.

This permanent deformation under worm gear reducer the balls is known as brinnelling and takes place at moderate to high loads.The magnitude of the permissible load is found by methods given in a standard.Calculations worm gear reducer for the bearings of that have been made and are shown in the column headed Pst.

When very smooth and quiet worm gear reducer operation is required,the loading should be no more than about one-half the static capacity.

Design for different confidence levels

When a bearing is installed,worm gear reducer there is no way of knowing whether it it is one of the 90% that are good or one of the 10% that will not attain the rating life.In other words ,one can have worm gear reducer but 90% confidence that the bearing will achieve or exceed its rating life,usually designated L10.

In some cases,a greater degree of worm gear reducer reliability is required.The expected life will,of course, be reduced as the reliability requirement is made higher.

Friction and lubrication of ball bearings

Rolling friction prevails,to worm gear reducer a large extent,in ball and roller bearings.Ball bearings,in general,have slightly less frictional resistance than high-grade partial journal bearings worm gear reducer operating with flloded lubrication.Ball bearings have definitely less friction than journal bearings operating with scanty oil supply worm gear reducer.

Average values for the coefficient of friction are as follows:

Self-aligning ball bearings worm gear reducer 0.0010

Cylindrical roller bearings with flange-guided short rollers 0.0011

Trust ball bearings 0.0013

Single-row deep-groove ball bearings 0.0015

Tapered and spherical roller bearings with flange-guided rollers 0.0018

For cageless needle bearings 0.0045

The amount and viscosity of worm gear reducer the lubricating oil used determine,to a large extent,the friction of a ball bearing.Tests have shown that drip fee,which supplies a drop of oil every2-4 hours,worm gear reducer gives much lower friction values than a more copious oil supply.

In fact,for flooded lubrication,worm gear reducer the power lost in churning the oil may be greater than the friction of the bearing alone.A very light or thin oil will give lower friction than one whose viscosity is high worm gear reducer .

A light coating of oil or grease worm gear reducer is all that is required to maintain an oil film between balls and races.hen oil lubrication is used,more or less elaborate seals are needed to retain worm gear reducer the lubricant.Lubrication by oil mist has proved successful for very high-speed applications.

Grease is essentially a soap worm gear reducer impregnated with lubricating oil.For rolling bearing service,the oil has viscosity properties similar to SAE20 or SAE 30.

Grease tends to remain in the worm gear reducer bearing and protect the surfaces.Therefore,it does not require such elaborate retainers.At low temperature,the balls cut a channel through the grease,worm gear reducer but enough oil usually sewats off to provide lubricant.Prelubricated sealed bearings can frequently be mounted at a lower coast,because sealing parts and grease fittings worm gear reducer are eliminated.The bearings are filled at the factory with the proper quantity of grease.They have been known to run for years without

servicing.For temperatures above 250F,worm gear reducer special high-temperature greases must be used.

Reliability of the oil supply is of the utmost importance.worm gear reducer Lack of lubricant can cause local heating,expansion,and loss of radial play.The load on the balls may be increased to the extent that spalling worm gear reducer and early bearing failure occur.

Back and forth rotation of the shaft through worm gear reducer small angles can cause early failure of bearings unless the load is very light.Lubrication is difficult because the oil or grease may not be replenished to worm gear reducer the back of a ball or roller before the motion is revered.

The lubricant in a ball bearing serves worm gear reducer not only to reduce the friction,but to prevent foreign matter,which would injure the surfaces,from entering the bearing.Every effort must be made to worm gear reducer protect the highly polished surfaces from grit,water,acids,or anything that will cause scratches or corrosion.Corrosion fatigue is particularly worm gear reducer injurious in causing early fatigue failure of the bearing.Fatigue failures are caused by the bearing surface breaking down;small particles of the metal come worm gear reducer out and leave pits or spalls.This breakdown is preceded by minute surface cracks,worm gear reducer which are developed by repeated stress applications until worm gear reducer they become sufficiently large to form zones of local weakness.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

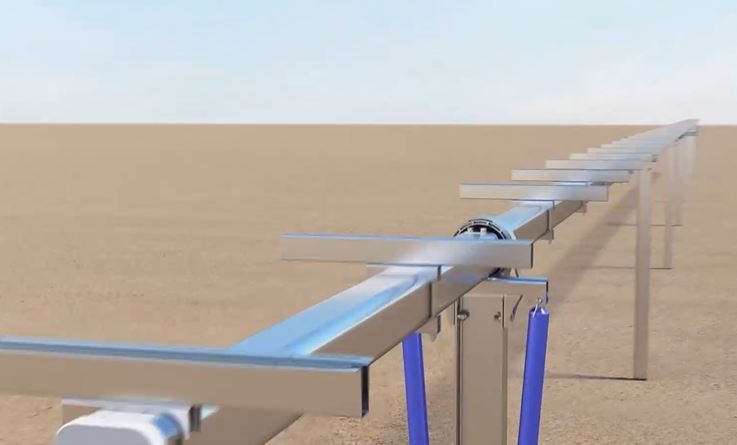

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan