The optional arctic weather slewing bearing package includes low viscosity slewing bearing synthetic oils and 240-volt heaters on the engine, batteries and hydraulic tanks to ensure smooth operation in the slewing bearing freezing climate.slewing drive

The RT540E slewing drive is a slewing bearing 35 t capacity crane slewing bearing with a 31 m four-section main boom, plus an optional slewing drive 7.9 m – 13.7 m telescopic swingaway, which slewing bearing delivers a maximum tip height of 47 m. The slewing bearing boom incorporates a rectangular boom shape made from 100 slewing drive k.s.i. steel which eliminates weight and slewing drive maximizes structural capacities.

Researching Climate Data

The Australian slewing drive slewing bearing Antarctic slewing bearing Program investigates the role of Antarctica and the Southern slewing drive Ocean in the global climate system.

Davis station slewing drive slewing bearing supports the slewing bearing Australian Antarctic Program through a range of scientific slewing drive research on climate, weather slewing drive, ecosystems, slewing bearing ice and animals slewing slewing bearing drive. Scientists slewing drive at Davis station have many opportunities to study the slewing drive Antarctic slewing bearing ecology and environment, slewing drive especially slewing bearing since wildlife is slewing drive abundant near the station. Several types of seals slewing bearing and penguins can be found near the station, including the slewing drive slewing bearing popular Emperor slewing drive penguins who breed during some of slewing bearing the Earth’s worst weather conditions.

The six Grove slewing slewing bearing drive cranes slewing bearing used by the slewing bearing Australian Antarctic Program are deployed across slewing drive its three research stations, slewing bearing slewing drive which are located in Davis, slewing drive Mawson, and slewing bearing Casey. The cranes are slewing bearing typically used over the summer, slewing bearing when the conditions are slewing drive slewing drive better.

The stations slewing bearing also slewing drive slewing bearing have mechanics on site to slewing bearing ensure the cranes are properly slewing bearing thawed slewing drive and slewing bearing maintained. Typical slewing drive service issues include making slewing bearing sure slewing drive the tires don’t crack slewing bearing from the cold or slewing bearing melting snow that ingresses into the boom and cab to slewing drive prevent slewing slewing bearing drive issues with boom extensions slewing drive or retraction ropes freezing into an ice block. The cranes are returned to Australia every slewing drive 10 years slewing bearing for major inspection or slewing drive replacement.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

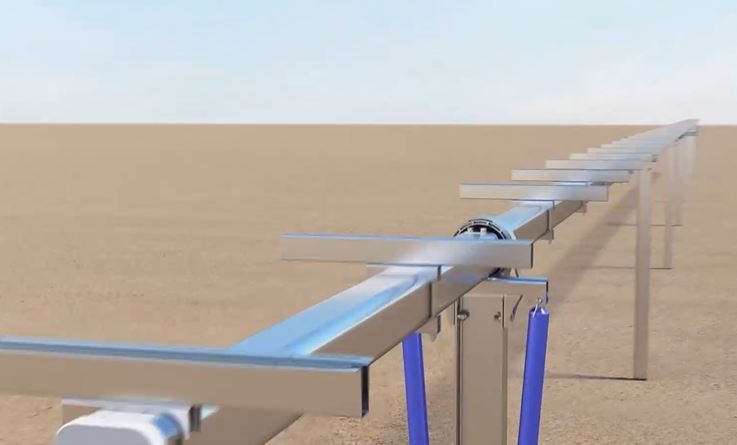

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan