More about the LG 1750 SX

The LG slewing drive slewing bearing 1750 SX was developed with the wind slewing bearing market in mind. However, slewing drive it can also be used in general industry slewing drive as a heavy lifting crane. It boasts a 155-metre main slewing drive boom, a derrick back slewing bearing mast (super lift), and a fixed slewing bearing jib of 12 metres. This is a typical configuration for installing larger wind turbines. It can also be equipped slewing drive slewing bearing with the 6m-wide boom slewing bearing system SX2 to give it more stiffness and ultimately a slewing drive higher capacity. This makes it future-proof in the wind slewing bearing market, where weights and lifting heights are constantly slewing bearing increasing.

While the slewing drive LG slewing drive 1750 slewing bearing crane model has been in use for several years, the SX version is the "mother of all LG 1750s" and slewing bearing is a real break from previous slewing drive boom system slewing drive upgrades. The main difference is its 3.5-metre wide boom system, as compared slewing drive to previous 3-metre boom versions. This gives it a slewing drive significant increase in slewing drive capacity.

More about the LTM 1450-8.1

The slewing drive LTM 1450-8.1 has an 85-metre telescopic slewing drive boom and 35-metre lattice boom extension (fixed jib). Optionally, slewing drive it can be equipped with an 84-metre luffing jib. It was developed as slewing bearing a simple, quickly deployable crane with slewing drive low mobilisation time slewing drive and slewing drive cost. Because of this, it is not equipped slewing bearing with the usual guided boom slewing bearing (super lift) that most 400-500t cranes have. However, its design means it brings sufficient capacity for many jobs.

The LTM 1450-8.1 will be used as an auxiliary crane on wind farm projects, where a larger 500t with super lift would slewing bearing normally have been slewing drive needed. This crane does the job well without the need for super lift. It also has very broad slewing bearing applications,slewing bearing ranging from 'taxi' jobs (its quick slewing drive slewing drive set-up time means it can perform several jobs in one day), slewing bearing as well as project work.

Safety standards slewing bearing

Both new slewing drive cranes are fully compliant with applicable safety standards and also slewing bearing have the latest available safety features. The slewing drive LTM 1450-8.1 slewing drive, for example, is slewing drive equipped with the Variobase slewing bearing system, which enables each of the four crane outriggers to slewing drive be extended to slewing drive a slewing drive different length. The crane's on-board control system measures slewing drive the outrigger lengths slewing drive along with other parameters, creating slewing drive a safer working environment by eliminating slewing bearing human error during rigging and crane slewing drive operations.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

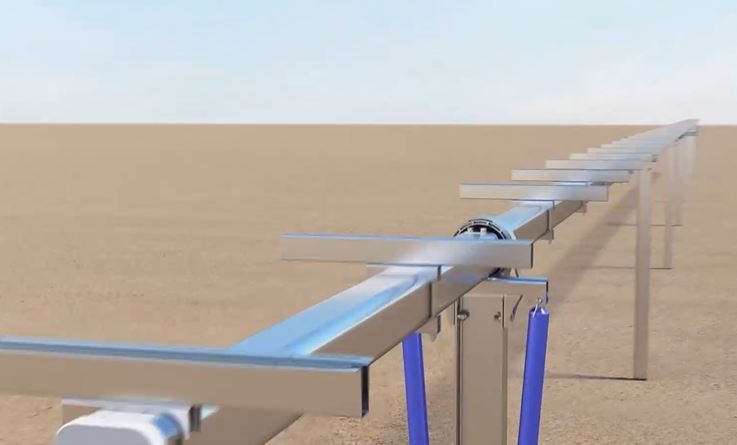

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan