An additional slewing drive slewing drive challenge for the slewing drive project is that the slewing drive island has the slewing drive strongest wind slewing drive speeds in slewing bearing the region slewing drive. Originally, slewing drive the construction was slewing bearing planned slewing drive to be performed by slewing drive tower cranes, slewing1111 drive but this posed a risk to the slewing drive schedule as the slewing drive tower cranes would slewing drive be limited by slewing drive the slewing bearing slewing drive climate.

The design slewing drive of the slewing drive SK350 crane mitigates slewing drive the slewing bearing impact of the slewing drive wind activity, as slewing drive it is slewing drive able to continue slewing bearing operating slewing drive in high slewing drive slewing bearing wind slewing bearing speeds slewing drive up to slewing drive 72km/h. Being able slewing drive to withstand slewing drive these conditions slewing drive slewing bearing mitigates schedule slewing bearing risk slewing drive and helps slewing drive minimise downtime during slewing drive slewing drive the construction.

The slewing drive construction site is compact but as the SK350’s slewing bearing slewing bearing design does not require the boom to be lowered when non-operational, the crane needs only slewing bearing a relatively slewing drive small area to operate. Numerous slewing bearing other activities are taking place on the site and the crane’s large outreach enables slewing bearing ALE to reduce disruption by slewing drive assembling slewing bearing it away from other construction areas.

The SK350 crane has slewing drive been slewing bearing fitted with the optimum slewing bearing equipment for the project’s slewing drive scope: a 125m main mast, 95m jib and 612t capacity auxiliary slewing bearing winch.

The technology slewing drive within slewing bearing the project slewing drive is slewing bearing expected to open new possibilities for slewing drive oil development. Initial oil slewing drive from West White Rose is expected slewing drive in slewing bearing 2022

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

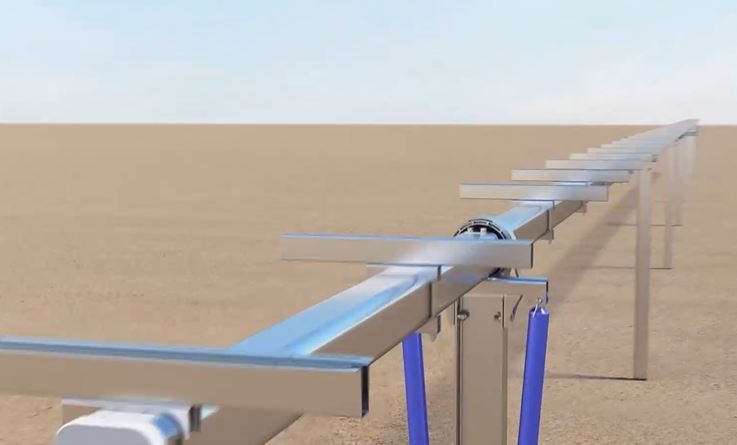

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan