The machine slewing drive removal could be motor-reducer carried slewing bearing out quickly motor-reducer and without any problems. The variable support base VarioBase® was helpful in order slewing drive to support the slewing bearing crane between the existing systems with only slewing drive partially motor-reducer extended slide bars. In addition, the LTC’s ability to slewing bearing telescopically slewing drive telescopic with the motor-reducer boom and to drive with load on the hook was needed motor-reducer. Gerd slewing bearing Müller, branch motor-reducer manager at slewing drive Salgert, who is responsible for the organisation slewing drive and planning motor-reducer of major projects and in particular for machine movement, is enthusiastic motor-reducer slewing drive about the slewing drive Liebherr compact crane slewing bearing: “With the LTC 1050-3.1, we can size classes. In motor-reducer today’s operation, for example, we had to slewing drive trade slewing drive slewing bearing machines weighing 6.2 to motor-reducer 18 tons. The LTC offers the possibility to cover everything, both the unloading of slewing drive heavy slewing bearing machinery as well slewing drive as slewing drive delicate work in these cramped conditions. Another motor-reducer advantage of the LTC 1050-3.1 slewing bearing is slewing drive that it can pass through gates of only 3 meters.”

The slewing drive RemoteDrive motor-reducer function is a consistent further motor-reducer development of the Liebherr crane slewing drive control LICCON2. Since its introduction 13 years ago, Liebherr cranes slewing drive have slewing bearing been equipped with the BTT mobile control motor-reducer and display unit via radio remote control. The LICCON2 mobile crane control motor-reducer motor-reducer also offers the possibility slewing bearing of a simple slewing drive extension for radio remote control of all motor-reducer crane functions of the upper car. In slewing bearing slewing drive addition to the corresponding software slewing drive in the crane, only one console with two master switches is required, into which the motor-reducer existing BTT is inserted.

What is new now slewing drive is the crane chassis process motor-reducer. It is possible for the first time with the compact crane slewing bearing LTC slewing drive 1050-3.1. In particular, fine-tuning between the motor-reducer remote control and the millimeter-precise motor-reducer implementation on the slewing drive crane was a challenge for Liebherr engineers and software experts slewing drive. Especially when every centimeter is important for slewing bearing bottlenecks, slewing drive the safety motor-reducer of people, cranes and the environment is paramount. And slewing slewing bearing drive this is exactly where RemoteDrive technology slewing drive is setting new standards in coordination with the motor-reducer LICCON slewing bearing crane control system developed by slewing drive Liebherr.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

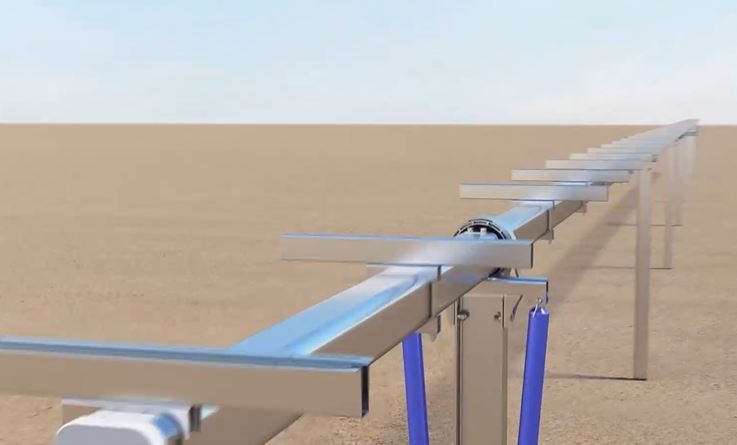

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan