For example, Gabriel Venzin, President of ABM Drives, shares how his company provides value-added services such as in-house engineering support to their customers. “ABM’s base business model is based on joint development of end-products with customer engineering input,” notes Venzin. “The products on most of our projects are being engineered in close cooperation with and input from the customer’s technical departments.”

Joint cooperation is the norm especially for components designed for specific, unique applications. One area where manufacturers are seeing increased demand is in automated guided vehicles (AGVs). A major trend in transportation has been in the direction of electric vehicles and here gearmotors excel. Some of the most common uses are in automated warehousing K Series Helical-bevel Gear Reducer applications such as automated T Series Right Angle Gearboxes storage and retrieval (AS/RS) systems. However, gearmotors can also be used in F Series Parallel Shaft Helical Reducer other vehicle applications such as in forklifts, lifting technology, construction equipment, and packaging X.B Cycloidal machinery, to name a few.

A typical requirement for gearmotors used in AGVs is that their size should be as compact as possible because of space limitations. And because AGVs are battery powered, the gearmotor ARA helical bevel gearbox power consumption needs to be minimized. One KRV Helical-Hypoid gear Reducer way to do this is to pair low-voltage dc motors with high-efficiency gearboxes. As dc motors have higher peak torque for a given size they can be smaller and lighter than other motor options.

For instance, brushless dc gearmotors from Brother are being used in AGV applications. There are Boat Winches worm reducer a range of options depending on the specific requirements, including the motor type and housing, but also differing motor voltages including 12, 24, and 48 V.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

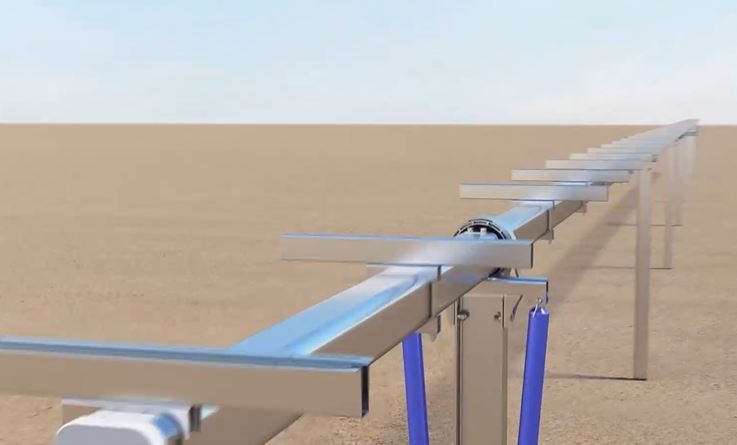

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan