A gear motor can be either an AC (alternating current) or a DC (direct current) electric motor. Most gear motors have an output of 1,200 to 3,600 revolutions per Boat Winches worm reducer minute (RPMs). These types of motors also have two different speed specifications: normal speed and the stall-speed torque specifications.

Gear motors are primarily used to reduce speed in a series of gears, which in turn creates more torque. This is accomplished by an integrated series of gears or a gearbox being attached to the main motor rotor and shaft via a second reduction shaft. The second shaft is then connected to the series of gears or gearbox to create what is known MB,MBN Speed Variator as a series of reduction gears. Generally speaking, the longer the train of reduction gears, the lower the output of the end, or final, gear will be.

An excellent example of this principle would be an electric time clock (the type that uses hour, minute, and second hands). The synchronous AC motor that is used to power the time clock will usually spin the rotor at around 1,500 revolutions R Series Helical Gear Reducer per minute. However, a series of reduction gears are used to slow the movement of the hands on the clock.

For example, while the rotor spins at about 1,500 revolutions per minute, the reduction gears allow the final secondhand gear to spin at only one revolution per minute. This is what allows the secondhand to make one complete revolution per minute on the face of the clock.

Gear Motors and Increased Force

Gear motors are commonly used in commercial applications where S Series Helical-worm Gear Reducer a piece of equipment needs to be able to exert a high amount of force in order to move a very heavy object. Examples of these types of equipment would include a crane or lift jack.

If you've ever seen a crane in action, you've seen a great example of how a gear motor works. As you have probably noticed, a crane can be used to lift and move very heavy objects. The electric motor used in most cranes is a type of gear motor that uses K Series Helical-bevel Gear Reducer the basic principles of speed reduction to increase torque or force.

Gear motors used in cranes are usually specialty types that use a very low rotational output speed to create incredible amounts of torque. However, the principles of the gear motor used in a crane are exactly the same as those used in the example electric time clock. The output speed F Series Parallel Shaft Helical Reducer of the X.B Cycloidal rotor is reduced through a series of large gears until the rotating, RPM speed, of the final gear is very low. The low RPM speed helps to create a T Series Right Angle Gearboxes high amount of force which ARA helical bevel gearbox can be used to lift and move the heavy objects.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

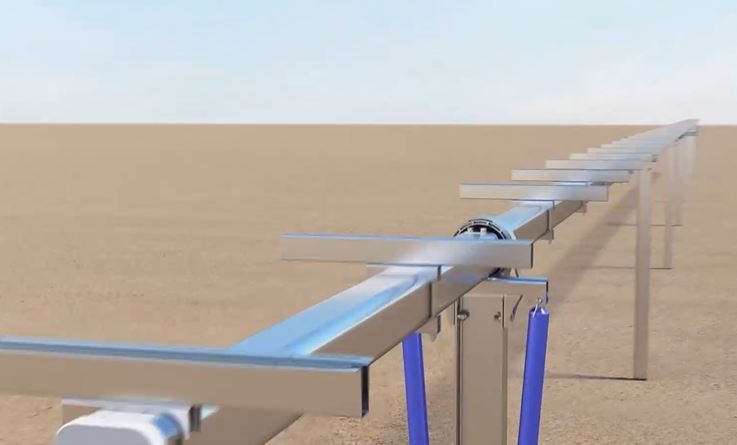

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan