Boundary or thin-film lubrication for worm gear reducer

Machine parts of worm gear reducer coated with a lubricant and rubbing together without a fluid film are a common occurrence in machinery.Such operation of worm gear reducer can also occur in a journal bearing for low values of the viscosity or speed or for high values for the load, as indicated by the left end of the curve.Such action,known as boundary lubrication ,worm gear reducer can also occur during starting,stopping,or the reversing of journal bearing.It can also occur during the running-in period of a new machine.The separation of the surfaces of worm gear reducer is of molecular dimensions.

The rules previously stated for dry friction apply also to boundary lubrication,with the following additions:

The friction force depends on the composition of the lubricant and its reaction with the contacting surfaces of worm gear reducer.

The friction force is influenced by the temperature and surface roughness of the bodies.

The friction force worm gear reducer is independent of the viscosity of the lubrication .The ordinary rules of hydrodynamic lubrication do not apply to boundary lubrication,and design equations for this type of service are not available.

Fatty acids,as found in certain animal and vegetable oils,worm gear reducer can be added in small quantities to the lubricant to give a friction-reducing quality distinct from the viscosity of the lubricant.These react with the surfaces to form very tough and durable coatings,worm gear reducer and at the same time provide a plane of low shearing strength on which the relative motion between the parts takes place.Massive seizure between the parts and worm gear reducer is thus prevented.Should the film be ruptured when two peaks come together exposing pure metals,instantaneous welding will occur worm gear reducer.Such welds of the high spots are immediately broken by the relative movement between the bodies,resulting in wear and increased friction force.

Boundary lubrication of worm gear reducer breaks down at elevated temperatures,resulting in a large increase in the worm gear reducer coefficient of friction accompanied by wear and surface damage.True boundary lubrication of worm gear reducer is difficult to achieve even in the laboratory.Usually,there will be sufficient lubricant present to form localized patches of film,which carry worm gear reducer part of the load while the remainder of the surfaces are rubbing without complete separation of the peaks of the two surfaces.The result of worm gear reducer is the so called mixed lubrication.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

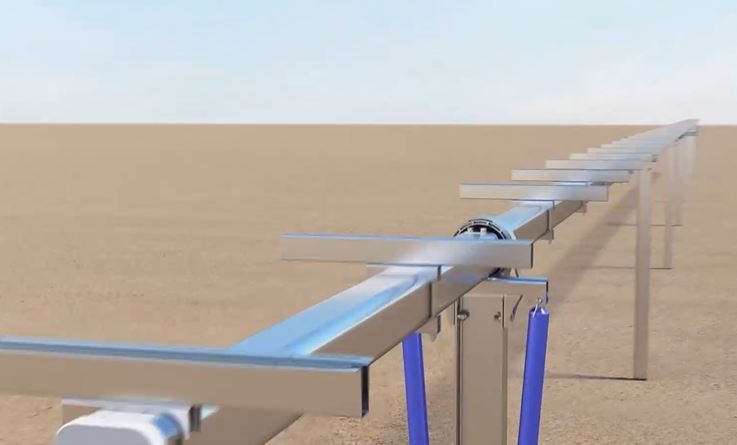

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan