Battery powered gearmotors and motors for mobile equipment and AGV applications are usually required to be as small and as efficient as possible. Designers of these mobile robots aim for the smallest possible motor footprint. Integrating sensors and actuator mechanisms with the gearmotor is a practical way of improving the use of available space.

The trend toward more custom designs also continues to impact gearmotor designs. “Many of our customers require custom electrical designs and mechanical features,” notes Mark Marhoefer, Director of Technical Research and Controls for Bodine Electric. “Typical customization of our gearmotors ranges from minor details like special tapped holes in the housings to custom ARA helical bevel gearbox magnetics, special castings, shafts, sensors, customized controllers and motor and control testing. We also conduct ongoing outdoors and environmental testing of these products to further validate out IP ratings.”

Others examples include adding custom castings to a gearmotor assembly that allowed an OEM to integrate their drive wheel mechanisms with the gearmotor, making the assembly and installation of the drive unit much easier and more compact. Bodine regularly incorporates custom feedback solutions within the motor design to allow the customer to easily interface the gearmotor Boat Winches worm reducer with their electronics. These solutions include many types of temperature sensors, various shaft feedback devices for speed and position sensing and custom feedback designs for actuator arms with limited range of motion. Especially with the rising interest in the industrial IoT, companies are seeing KRV Helical-Hypoid gear Reducer an increasing the demand for sensor technologies at the motor. This typically includes increased demand for motor temperature sensors and sensors for velocity or position feedback.

Customization also includes more integration up front. For instance, motors with actuators designed for defined purposes such as lift actuators, rotating actuators and wheel drives. Also, gearmotors with integrated controllers allow the envelope to be more compact and eliminates the wiring typically required between the controller and the motor.

“Instead of selling a motor X.B Cycloidal and letting the customer do the integration of actuator components for the application, we work with them to design a product that directly interface to the drive mechanisms,” explains Marhoefer. “This might involve integrating a pinion gear or actuator arm on our drive shaft with provisions to locate and mount the gearmotor. This will provide the T Series Right Angle Gearboxes correct fits and tolerances to allow the customer to bolt the gearmotor into their equipment and use it with minimal effort at the time of assembly.”

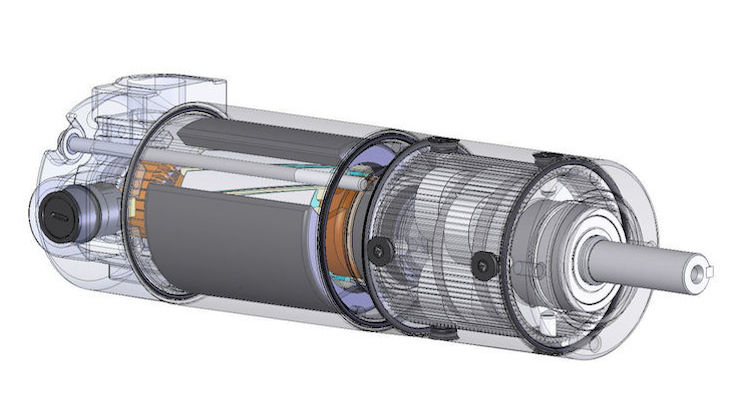

More integration also means gearmotor designs that are smaller and more compact. For instance, Bodine recently introduced an integrated planetary gearbox design that allows the gearmotor to produce twice the torque from a smaller diameter gearbox than comparable parallel shaft gearboxes. “Our customers benefit from the higher torque density and smaller overall gearmotor size, and the integral gearhead design eliminates the need for mounting flanges, couplings, and all related alignment challenges that come with separable gearhead assemblies,” adds Marhoefer.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

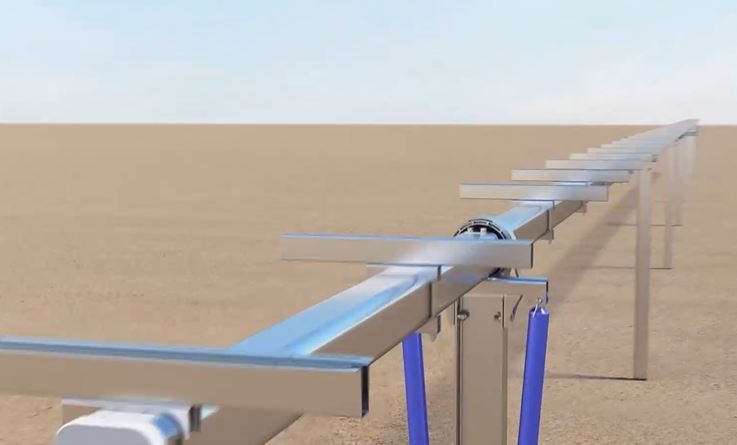

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan