BTLS slewing bearing offer both bare rentals of the equipment, as well as slewing drive providing an operator should the job require it. Bridge says that larger operators have told him that they consider smaller cranes to be ‘an incident waiting to happen,’ slewing drive due to the increased hazards of the small quarters where the cranes are often used slewing bearing – a crane operator used to operating outdoors with the sky above their heads now slewing drive has to remember there’s a roof a few feet up. So, when the situation calls for it, BTLS will provide an operator.

“We slewing bearing are very specific with where we take our equipment, even slewing drive when we rent it, we want to make sure that we know what our customer’s needs are,” says Bridge. “We don’t mind bare renting, but we want to make sure that they get slewing drive the right piece of equipment. So, we ask lots of questions. A lot of times, people get these machines and they don’t really know how to use them properly. On certain jobs, it’s easier for us to just come and do the job and not have to come back again rather than drop the machine off, show them how to run it, wait two days and then go back and pick it up.”

BTLS slewing bearing primarily offer slewing drive Jekko-built mini-cranes and Spydercranes slewing drive, by UNIC – Bridge cites those two brands, as well as Maeda, as the top names in the sector.

“The slewing bearing UNIC 295, in my opinion, is probably the most versatile slewing drive crane [in the mini-crane sector],” says Bridge. “The Jekkos are probably a little bit more sophisticated. They have some nicer options for hydraulic jibs andslewing drive stuff like that. The way that they slewing drive operate, they’re a very smooth machine. Not saying that the UNICs aren’t, it’s just that the remote makes them a little bit tougher to slewing drive operator. It just slewing drive requires a little bit more skill.”

Bridge slewing bearing says that every piece of slewing bearing equipment BTLS slewing drive has is specific for slewing bearing certain types of jobs. It’s slewing drive difficult to have the right machinery for every purposed, as slewing bearing depending on the location and circumstances everyone wants slewing drive something different, even down to how the unit is powered.

“We have slewing drive slewing bearing customers that do a lot of curtain wall slewing drive slewing bearing install, so they’re always outside,” says slewing drive Bridge slewing drive. “Working in the slewing bearing cold weather in the winters, battery powered slewing drive equipment slewing bearing doesn’t work very slewing drive slewing bearing well for them. But we slewing drive also have those same slewing drive customers that do work inside buildings slewing bearing on maintenance slewing drive or slewing bearing construction slewing bearing and they all want batteries. There’s a huge variety of equipment that slewing drive you can have, but its making the slewing bearing choice of what you can work slewing drive with.”

Bridge slewing drive slewing bearing acknowledges that the smaller slewing bearing slewing drive overheads slewing drive related to this business model slewing bearing are both literal and figurative – serving slewing drive this niche sector does not slewing slewing bearing drive guarantee a slewing drive massive lucrative slewing bearing return on investment slewing bearing. And they do slewing drive end up competing with larger companies that have slewing drive some slewing bearing mini-cranes as slewing drive slewing drive slewing bearing part slewing bearing of a larger fleet. But BTLS slewing bearing have made it work by diversifying slewing bearing into other small-scale slewing drive offerings,slewing bearing including vacuum slewing drive slewing bearing glass lifting slewing drive products slewing drive and manlifts.

Between slewing drive the mini-cranes and slewing drive the glass work, slewing bearing BTLS slewing drive ’s work has been very intricate – not necessarily slewing bearing challenging, Bridge notes, as they’ve gotten used to it, but slewing drive certainly slewing drive intricate and often only with millimeters slewing drive of clearance. Their mini-crane offerings have been utilized slewing drive slewing bearing in many unique locations slewing drive (such as installing a curtain wall slewing bearing on the 30th floor of Edmonton’s still-under-slewing drive construction Stantec building), and slewing bearing under very cramped circumstances.

“A lot of slewing drive people don’t get to slewing drive experience a slewing drive lot like crane operators,” says slewing drive Bridge. “It’s very tight slewing driveslewing drive. Sometimes, you have slewing bearing to fish the jib through a hole that’s slewing drive one foot square to do a pick through there. It’s slewing bearing slewing drive slewing drive just interesting work slewing drive slewing bearing.”

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

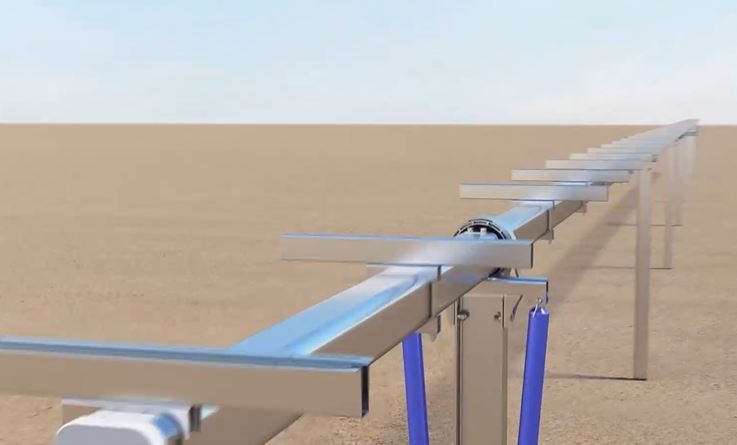

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan