Throughout the OSHA rules, there is not a slewing drive crystal clear slewing bearing definition for “maintenance”, nor a clear distinction between terms such as “maintenance”, “repair”, or “refurbishment.” “Maintenance activities” can be defined as slewing bearing making or keeping a structure, fixture slewing bearing or foundation (substrates) in proper condition in a routine, scheduled, or anticipated fashion slewing drive. This definition slewing bearing implies “keeping equipment working in its existing state, i.e., preventing its failure or decline.” However, this definition, (taken from the directive on confined spaces) is not slewing bearing dispositive; and, consequently, determinations of whether a contractor is engaged in maintenance operations rather than construction slewing drive activities slewing bearingmust be made on a case-by-case basis, taking into account all information available at a particular site.(3)”

“Construction work is also not limited to new construction, but can include the repair of existing facilities or the replacement of structures and their components. For example, the replacement of one utility pole with a slewing drive new, identical pole would be maintenance; however, if it were replaced with an improved slewing bearing pole or equipment, it would be considered slewing bearing construction. (4)”

“In addition to the concept of one-for-one slewing bearing replacement slewing drive versus improvement, the scale and complexity of the project are relevant. This takes into consideration concepts such as the amount of slewing bearing time and material required to slewing drive complete the job. For example,slewing bearing if a steel beam in a building had deteriorated and was to be replaced by a new slewing bearing, but identical beam, the project would be considered a slewing drive slewing bearing construction repair rather than maintenance because of the replacement project’s scale slewing bearing and complexity. Also slewing bearing, if a bridge was to be stripped and re-painted, that would be considered construction work even if the repainting were done on a scheduled slewing bearing basis slewing bearing. Replacement of a section of limestone cladding on a slewing drive building, though not necessarily a large project in terms of scale, would typically be considered construction because it is a complex task in view of the steps involved slewing drive and tools and equipment needed slewing bearing to do the work. (4)”

Simply adding a mobile crane to slewing drive maintenance work could raise the level of work to the scope of slewing drive slewing bearing construction.

The interpretation slewing bearing provided by OSHA shows slewing bearing that it does not matter who uses the slewing bearing crane or where the crane is slewing drive being used, if the crane is performing work that could be classified as slewing drive slewing bearing construction then the construction standards apply. The type of crane being used will slewing bearing affect which standard slewing drive applies, 29CFR1926.1438 (a) excludes the “slewing bearing following slewing drive equipment when slewing bearing slewing bearing used in construction and permanently installed in a facility: overhead slewing drive and gantry cranes slewing bearing, including semi gantry, slewing bearing cantilever gantry, wall cranes, slewing bearing storage bridge cranes, and others having the same slewing drive fundamental slewing bearing characteristics.(5)”

“In other slewing drive instances, where an slewing bearing activity cannot be easily classified as construction or slewing drive maintenance even when measured against all of the above factors, the activity slewing drive slewing bearing should be classified so as to allow application of the more protective 1910 or 1926 slewing drive standard, depending on the hazard. In such cases the citation slewing drive should be issued in the alternative with the emphasis on the more protective standard. (3)”

Since slewing drive crane operator qualifications/certification in the construction standards are more protective than the slewing slewing drive drive general industry standards, slewing drive when there is a slewing bearing question as to whether an activity is construction or general industry then the slewing drive construction slewing drive standards slewing drive apply.

It is CICB’s slewing drive recommendation that all crane operators be training and qualified/certified to the new Crane and Derrick slewing drive Standard.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

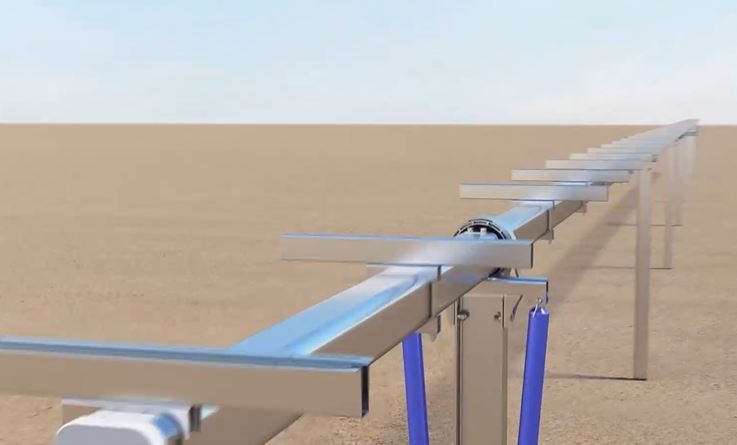

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan