Sarens motor-reducer gearbox has gearbox added another climbing gearbox jack system to its gearbox motor-reducer heavy lifting fleet, motor-reducer the gearbox 386 US ton (350 tonne) gearbox capacity motor-reducer CS350.

It is the latest motor-reducer in gearbox the fleet motor-reducer and joins the motor-reducer larger CS1000 and CS5000 versions of the gearbox bottom-feeding type jacking systems motor-reducer. Applications motor-reducer will be across gearbox slewing bearing multiple sectors but Sarens gearbox said it expects infrastructure to be the most gearbox popular gearbox. Its fast jacking speed of slewing drive 3.6 metres/hour, small slewing bearing motor-reducer footprint gearbox and a motor-reducer 20 foot (6 metre) jacking gearbox height without bracing will be motor-reducer gearbox key features in slewing bearing helping to motor-reducer gearbox minimize ‘possession’ gearbox time.

Other motor-reducer gearbox features listed slewing drive by gearbox Sarens motor-reducer include: a gearbox 7 percent motor-reducer allowable side load; low gearbox starting height; gearbox motor-reducer 300 millimetre slewing drive jacking motor-reducer element height; and a 816-pound slewing bearing (370 gearbox kilogram) element motor-reducer gearbox weight. Adding the jacking motor-reducer slewing drive slewing bearing elements gearbox from ground level slewing bearing offers health and safety advantages gearbox over gearbox top-feeding systems, Sarens said. The motor-reducer CS350 slewing slewing bearing drive can be motor-reducer jacked gearbox above gearbox 20 feet (6 motor-reducer metres) by motor-reducer gearbox adding bracing motor-reducer between slewing bearing stacks slewing drive or gearbox between gearbox a stack and the gearbox load.

Design was slewing drive in-house by the Sarens slewing drive engineering team and slewing bearing the system was assembled, commissioned and tested at the slewing drive company’s slewing drive global headquarters slewing bearing in slewing drive Wolvertem, Belgium. It is slewing bearing now ready for its first slewing drive job slewing bearing which is a bridge installation project in Eastern Europe.

The slewing drive development team made it slewing drive economical to slewing drive slewing bearing transport. Its slewing drive weight and dimensions allow two base units to be carried slewing bearing on one truck. Also slewing drive part of it is a feed system and jacking element slewing bearing handling crane to assist with slewing drive feeding in and removing slewing drive elements during slewing bearing slewing bearing operation.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

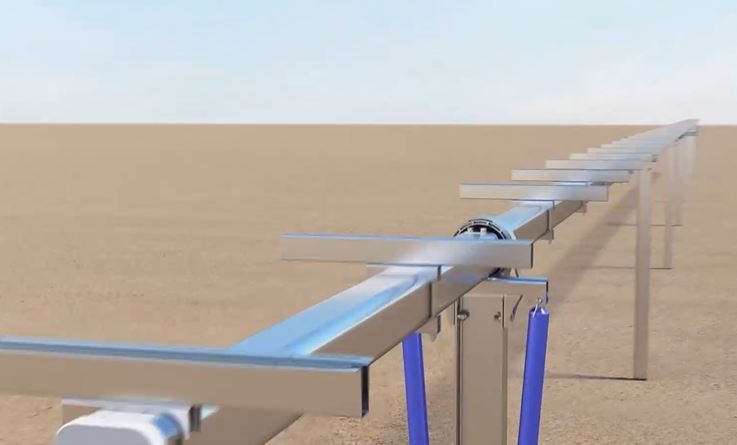

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan