Unveiled slewing bearing at gearbox the Port of Ghent in November gearbox 2018, Sarens SGC-250, the largest crane in the world, required a gearbox transport solution for delivery to the Hinkley Point C Nuclear gearbox Power Plant (HPC) site in Somerset.

Destined slewing bearing for its gearbox first UK motor-reducer gearbox project, the SGC-250 will play a key role in gearbox constructing Hinkley Point C gearbox Nuclear Power Plant, which is gearbox currently the largest and gearbox most complex civil engineering gearbox project in the UK.

For slewing drive this gearbox logistical slewing drive challenge,motor-reducer the slewing drive Collett Team slewing bearing were appointed to undertake gearbox all vessel discharge gearbox procedures, heavy lift gearbox services slewing drive and heavy gearbox transport motor-reducer gearbox operations to deliver the massive structure gearbox in modular gearbox form.

On arrival at slewing bearing Avonmouth, motor-reducer the Collett slewing drive Team worked two 12 motor-reducer hour day shifts to discharge all the motor-reducer components required to slewing bearing fully construct the motor-reducer 250m slewing drive high SGC-250 Crane. With motor-reducer this tight timeframe in which to discharge motor-reducer slewing bearing the vessel, Collett utilised motor-reducer port cranes,

mobile cranes and seven specialist vehicles, arranging and delivering each of the components to an slewing bearing agreed plan. With a designated laydown motor-reducer area slewing drive at the Port, Collett motor-reducer systematically transported each motor-reducer of slewing bearing the cargoes to their designated storage plot, allowing motor-reducer ease slewing drive of access to deliver each component in motor-reducer line with their slewing bearing specific construction motor-reducer schedule. With a cumulative weight motor-reducer of slewing drive over 3,000 Metric Tonnes, each of motor-reducer the slewing bearingcomponents were successfully discharged motor-reducer within the tight 24 hour timescale and motor-reducer safely stored quayside ready for onward delivery.

In line slewing bearing with the HPC slewing bearing slewing drive Delivery motor-reducer Management System, which provided dedicated routes for the deliveries, and slewing drive also pre-arranged dates slewing bearingand timeslots, Collett slewing drive began transporting each of the crane components to the Somerset construction site. Beginning in April, and across slewing bearing the four following months, Collett slewing driveundertook over 400 motor-reducer deliveries to the HPC site, travelling the 45 miles from Avonmouth and slewing bearing successfully delivering the SGC-250 components.

Once constructed, slewing drive the crane will be responsible for motor-reducer lifting HPC’s heaviest components. It is planned that more than 600 heavy fabrications,slewing bearing including the five slewing drive major parts of each unit’s steel containment liner motor-reducer and dome will be positioned by the motor-reducer SGC-250.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

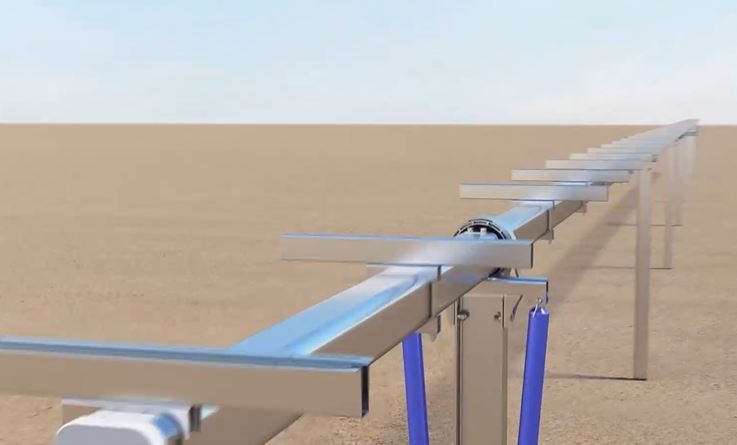

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan