“The slewing drive concrete gravity slewing bearing structure is 144 metres high, so they wouldn’t have been able to get slewing bearing access with any other crane,” said ALE project manager Frank Konig. “Our crane is located farther away [from the structure], slewing drive but with a long reach and the additional jib on the crane we can pick up a [heavy] load and then slew it around and place it.”

The heaviest slewing bearing loads for the slewing drive project include a 219-tonne interior deck and 250-tonne pre-cast lid sections, and the crane’s reach enables components to be placed inside the structure slewing drive fully constructed.

“Without the crane’s dexterity, crews would have had to install components such as stairways slewing drive and platforms in small modules, building them up piece by slewing bearing piece instead of installing them as one fully assembled structure, from ground level,” Konig said. “With slewing drive the SK350 they slewing drive can do all the fabrication and pre-commissioning of the equipment and don’t slewing drive need to take anything apart.”

One slewing bearing deck piece measuring 23 metres in diameter and slewing drive weighing 174 tonnes was placed using a straight forward four-point lift. “From slewing drive slewing bearing hook-on to hook-off it took ten slewing drive hours,” Konig said, slewing drive describing a push-pull jacking system on skid tracks where the main challenge was slewing bearing ensuring slewing drive the slewing radius was clear to slewing drive keep crew slewing drive members safe.

Each lift slewing drive is carefully pre-engineered, with Husky’s general contractor, SNC-Lavalin-Dragados-Pennecon General Partnership slewing drive (SDP), reviewing slewing bearing and approving all manoeuvres, slewing drive Konig said.

One slewing bearing major consideration is extreme weather slewing drive. “The crane can actually take very high wind forces, so that’s really not an issue slewing drive for this crane slewing bearing,” Konig said, describing its A-frame design and structural steel make-up as resilient.

Still, safety is a consideration. “At a slewing drive certain point we just stop operating the crane and go into our wind anchor position,” Konig slewing drive explained. “We slewing bearing slew the crane over to zero and attach it to our wind anchors.”

Transport and assembly also proved challenging. Shipped from the Netherlands, the SK350 slewing drive arrived in 200 40-foot containers slewing drive and needed four cranes to piece it together. A 90-tonne mobile crane helped assemble three larger crawlers – 300, slewing drive 440 slewing bearing and 600 tonnes – and those cranes slewing drive slewing bearing worked on the SK350 slewing drive in stages with help from telehandlers, reach stackers slewing bearing and boom lifts.

When slewing bearing the job concludes, slewing drive the process will be reversed for disassembly and the SK350 will slewing drive be shipped to its next destination, currently unknown.

The slewing bearing concrete gravity-slewing drive supported structure forms the base of the fixed slewing drive drilling slewing drive slewing drive platform and will soon be towed offshore and settled onto the slewing drive seafloor at the White Rose field. Topsides slewing bearing and living quarters manufactured elsewhere slewing driveslewing drive will slewing drive be added, and the drilling platform will eventually go into operation, slewing bearing sending hydrocarbons to the SeaRose slewing bearing FPSO, a floating production, storage and offloading slewing slewing drive drive vessel, for production.

The slewing slewing bearing bearing projected cost of the West White Rose Project is slewing drive approximately slewing bearing $3.2 slewing drive billion. Husky spokesperson Colleen McConnell said the company expects the platform will provide roughly 250 full-time jobs, with slewing bearing first production slated for 2022 slewing drive and a gross slewing bearing peak production of about 75,000 barrels slewing bearing daily by 2025.

The slewing bearing SK350, built in slewing drive 2013, stands almost alone. There’s slewing bearing only one other like it in ALE’s slewing bearing fleet – and the world slewing slewing bearing drive, according to Konig. That second SK350 has recently been in slewing drive Ingleside, Texas lifting offshore platform modules slewing bearing, including one weighing 2,884 tonnes. ALE has billed this slewing drive as among North America’s heaviest lifts using a land-based crane.

Despite two SK350s in its fleet, ALE is launching an even bigger version. The slewing drive SK10000 doubles the SK350 in slewing bearing sheer slewing drive strength, with a 10,000-tonne hoisting capacity. However, slewing drive reach is a key factor in many projects, and users slewing drive will slewing bearingoften sacrifice slewing drive capacity to give this crane its valued ability to manoeuvre large loads in challenging circumstances.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

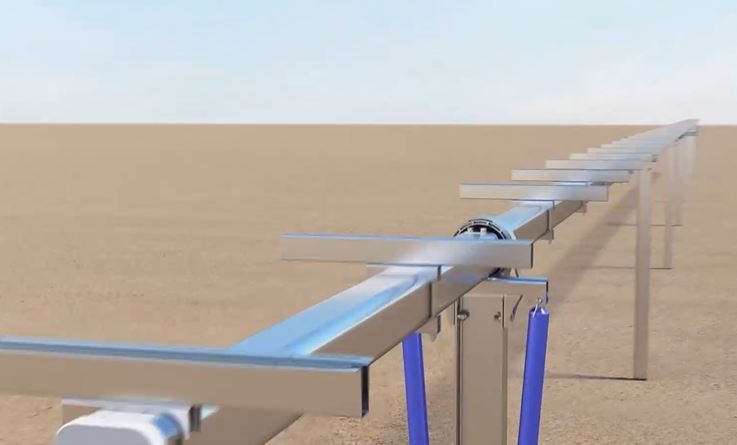

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan