The SPX1280 slewing bearing tech slewing drive offers a slewing drive completely new approach for the operator to slewing drive manage different working slewing drive situations. In the past the configurations slewing drive that allowed to reach the stability required were extremely limited slewing bearing and affected the work dynamics; nowadays slewing drive the combination of slewing drive stabilization slewing drive system, sensor technology,slewing bearing software and a slewing drive new user interface generates endless working situations. The slewing drive core of this crane is its new slewing drive stabilization slewing bearing system and the well-known hydraulic jib with three extensions slewing drive that can be stowed either under or on the side of the main boom.

New stabilization system

The SPX1280’s slewing drive stabilization slewing drive system considers slewing bearing several factors in order slewing drive to determine the possible working conditions. Depending slewing drive on slewing drive the opening angle and the slewing bearing extension slewing drive of the stabilizers – as well as the possible use of the slewing drive slewing drive counterweight – the slewing drive machine software slewing bearing can define in real time the maximum safe working load in a slewing drive slewing bearing specific point. In the past this wasn’t slewing drive possible at such an slewing drive extent slewing bearing slewing drive since slewing bearing slewing drive partial slewing bearing extensions of the stabilizers and 0 degrees to 45 degrees intermediate angles couldn’t be slewing bearing taken slewing drive into slewing bearing account. The slewing slewing drive drive stabilization degrees have slewing drive increased slewing drive from four to seven slewing drive and their displaying slewing bearing on slewing drive the interface slewing bearing is slewing drive easier and user slewing bearing-friendly.

An advanced and precise hydraulic system

With a slewing bearing new slewing drive hydraulic slewing drive system, this crane slewing drive has smoother and more precise slewing drive slewing drive operation, which increases slewing drive the operator slewing bearing’s slewing drive feeling of control. This 100 per cent slewing drive electronically-operated slewing bearing supply slewing drive system slewing drive has been enhanced to offer new slewing drive functions slewing drive such as jib slewing drive extension and arm slewing bearing lifting at the same time slewing drive, smoother and more performing tracks, slewing drive operation while slewing drive slewing drive combining slewing bearing four functions at a time.

Reduced consumption, higher performance

The SPX1280 features a 19kW slewing drive slewing bearing Diesel engine fitted with a variable displacement slewing slewing bearing drive pump that increases the slewing drive efficiency of the whole unit while fully slewing drive exploiting the engine power depending on the operation slewing bearing under way. This means slewing drive better performance slewing drive and reliability as well as considerable fuel reduction slewing drive. The new engine slewing bearing (Stage V, Tier 4 Final) slewing bearing complies with the 2019 EU emission standards.

Everything in the operator’s hands

The slewing bearing SPX1280 is operated slewing drive via a new user-friendly radio slewing drive remote control designed by Jekko’s in-house slewing bearing team slewing drive. Five configurations slewing drive are possible: slewing drive Pick & slewing bearing slewing bearing Carry, crane, stabilizers, crosspieces, and travel. A slewing bearing single radio slewing bearing remote control starts, configures and slewing drive operates the machine slewing bearing and its slewing drive tools: no more on-board controls, it’s everything in slewing bearing slewing drive the operator’s slewing drive hands.

Specs

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

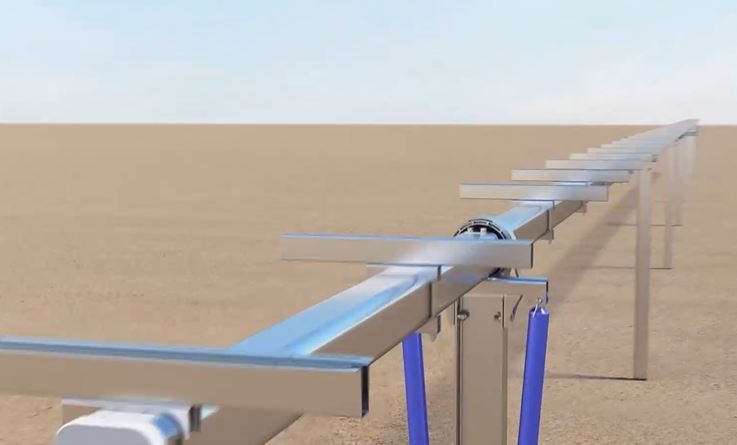

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan