“Konecranes slewing bearing and Demag have a slewing drive leading position worldwide in automated storage and retrieval systems (ASRS) slewing drive using cranes,” says Juergen Gieske, vice president, crane sales slewing drive. “Since Konecranes and Demag joined their slewing drive experiences and resources, we are able to put the best of both systems to work for our customers. One benefit of this slewing drive merging of brands is our ability to leverage slewing drive extension modules for our slewing drive Autostore ASRS paper roll handling cranes to slewing drive communicate with all other devices slewing drive and technology associated with the slewing drive customer’s manufacturing execution system (MES) – such as the slewing drive conveyors, printers and shipping protocols.”

Gieske also noted that overhead cranes using vacuum or slewing drive mechanical roll lifter technology provide damage-free roll handling that is the densest by volume of any warehousing solution.”

“The most common alternative to cranes is the use slewing slewing bearing drive of manual operators driving lift trucks with roll clamp attachments,” Gieske says. “These clamps often result in roll damage, delayed slewing bearing shipments, unwanted costs slewing drive and dissatisfied downstream customers. The lift trucks also require much more warehouse real estate to accommodate slewing bearing the aisle-ways required to navigate slewing drive at floor level – not to mention the lift truck’s limited roll vertical stacking heights.”

But the ASRS is slewing drive not the only impressive slewing drive aspect slewing drive of this installation. The slewing drive SMARTON model wet-end and dry-end cranes are slewing bearing designed for a slewing drive high moisture slewing bearing and high temperature environment, slewing drive rated IP66 with slewing drive many stainless slewing bearing steel features. Each crane features three top-slewing drive slewing bearing running trolley hoists in capacities of slewing drive 50/100/50 metric slewing bearing tons, plus two slewing drive 10-ton slewing drive auxiliary monorail slewing drive hoists slewing drive for additional material handling capabilities slewing bearing. This amounts to five trolley/hoists on each slewing drive crane.

In addition, the two 92-foot-span SMARTON slewing drive cranes are equipped with rotating paper roll spreader slewing drive beams to slewing bearing handle the 12.5-foot diameter x 27-foot slewing bearing long slewing drive parent rolls slewing bearing.

After the parent rolls are slewing drive slewing bearing processed into slewing drive smaller medium and linerboard slewing bearing rolls weighing up to 10 tons each, conveyors move them into one of slewing bearing two paper slewing bearing warehouse bays. Each slewing drive bay is slewing drive serviced by two 7-ton, 120-foot span, CMAA Class F, ASRS high-density warehouse cranes equipped slewing bearing with vacuum slewing bearing lifters that pick up the slewing drive rolls and store them in slewing drive vertical columns up to four rolls high. Bar coding allows each roll to be identified slewing bearing individually and scanned into the Warehouse slewing drive Management System (WMS)slewing drive slewing drive Level Two (2) where slewing bearing the slewing bearing crane software is completely responsible for inventory and retrieval.

Green Bay slewing drive Packaging’s director slewing drive of logistics slewing bearing Frank Miller says that Konecranes automatic storage and retrieval slewing bearing system was a critical component for the new mill.

“There’s no way slewing drive that we could slewing drive store the amount slewing bearing of paper that we need to on our site without this slewing drive Konecranes technology,” says Miller. “Konecranes ASRS enabled us to store more paper in a much smaller area than either slewing bearing a standard slewing drive warehouse or high density storage rack type application. A high density rack application is linked to the size slewing bearing of the roll you are going to manufacture, and there’s not a lot of flexibility if your roll sizes change in width or diameter. Konecranes application allows slewing bearing us the flexibility to have different trim widths, high density and high speed, and we needed all three of these things.”

Green slewing drive Bay slewing drive Packaging’s manufacturing protocol calls for the Autostore slewing drive ASRS cranes slewing bearing to operate 24 hours a day, seven days a week. They will receive slewing drive rolls into the warehouse, then retrieve them and place them onto slewing bearing conveyors to be delivered to the shipping docks. There, they will be slewing drive removed by lift trucks and loaded onto trucks or rail cars.

“Initially we considered a solution that picked up rolls with manual grippers, using a clamp slewing drive,” says Miller. “But the Konecranes slewing bearing slewing drive team recommended a vacuum lifter. It reduces the distance between the rolls from slewing drive eight inches to four inches, giving us higher density storage slewing drive and 20 percent more speed. That was a very important feature, and the vacuum lifters are able to slewing slewing bearing drive maintain a very high level of safety. If there slewing drive is a power failure it can maintain a roll suspended slewing drive up to 45 minutes.”

Green Bay Packaging also purchased three maintenance cranes slewing drive from Konecranes proven slewing bearing CXT series, slewing bearing which will slewing drive be key to the upkeep and reliability of the plant. These include a 5.5-ton core-handling crane, a 16.5-ton slewing drive vacuum blower slewing bearing crane and a 16.4-slewing drive ton shop area slewing drive crane. All three are built with high moisture slewing drive protection and IP66 stainless steel slewing bearing electrical designs.

Konecranes will also provide the runway rail, power supply and slewing drive installation for slewing drive the nine cranes. Commissioning, slewing drive load testing and operator slewing drive training round out the project’s slewing drive scope, which is expected to slewing bearing be fully operational in the spring of slewing drive 2021.slewing bearing

Green Bay slewing drive Packaging’s Frank Miller and Warehouse Area Project Manager slewing drive Joseph slewing bearing VerVelde visited Konecranes slewing drive headquarters in slewing drive Finland with their team as part of their research for this state-of-the-art project, and toured multiple sites in slewing drive Europe where Konecranes slewing drive roll storage technology was making a difference for paper producers slewing bearing there.

“We saw that the slewing drive Autostore ASRS provided a high level of integration in the warehouse, using slewing slewing bearing drive the cranes, conveyors and slewing drive warehouse management system to manage the entire put-away, storage and pick process,” said Miller. “We slewing drive felt that Konecranes was slewing drive the primary player in this technology, and had the global footprint from an engineering and resource slewing bearing standpoint to handle a project slewing drive of this magnitude. That gave us a lot of confidence.”

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

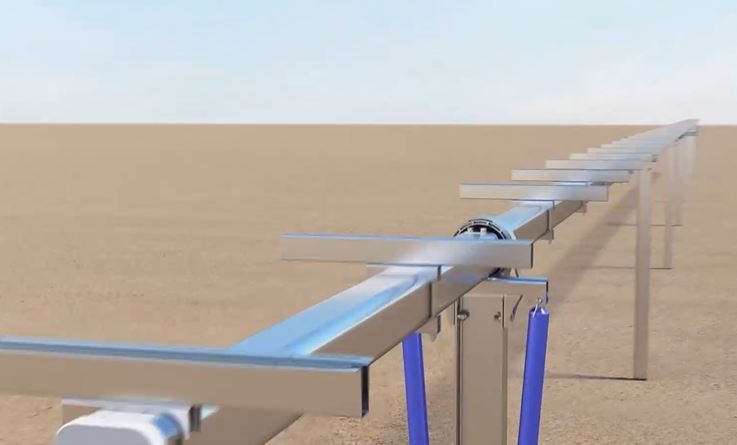

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan