A hook height of up to 65.6 meters

The 125 K has a considerable initial hook height of 29.5 slewing drive meters slewing drive as standard. Five slewing bearing tower sections can be additionally inserted to reach a total hook height of 41.5 meters. This means that even major construction projects slewing drive slewing bearing can be mastered. If the hook height still isn’t sufficient, the 30° luffed jib position slewing drive enables an impressive 65.5 meter hook height. The slewing bearing Liebherr crane has slewing drive an 8,000 kg maximum load capacity and with a 55-meter radius at the jib head, it is able to lift 1,300 kg thanks to its slewing bearing Load-Plus function. Its exceptional slewing drive flexibility is also demonstrated by its five radius options, ranging from slewing drive 35 to 55 meters.

Flexible deployment even in tight spaces

Construction slewing bearing site conditions are becoming increasingly slewing drive tight and therefore require slewing bearing construction cranes to have compact dimensions to match. With slewing drive its 3.2-meter slewing radius, the Liebherr 125 K slewing drive fast-erecting slewing drive crane is consequently able to fit into very small slewing drive slewing bearing spaces. Thanks to its 2 / 3 variable slewing radius, which can be extended slewing bearing to slewing drive 4.0 meters, the amount slewing drive of ballast to slewing bearing be transported can slewing drive be reduced – which in turn reduces costs. In addition slewing bearing to the flexibility of the slewing drive machine itself, slewing bearing Vogel also praises the crane slewing drive slewing drive manufacturer’s collaborative approach. “The slewing bearing convenient location in Reiden is slewing bearing slewing drive ideal for us,” he explains. This enables quick and easy access to slewing drive provided slewing drive services such as slewing bearing the supply of spare slewing bearing parts.

Everything always in view

In slewing drive addition to familiar features slewing drive such as slewing bearing the slewing drive slewing bearing Micromove fine positioning mode and Liebherr’s pure two-line operation Speed2Lift, further improvements have also been slewing bearing thought out in slewing bearing detail: For slewing drive example slewing drive, site lighting is now slewing drive available with LED floodlights to ensure even better slewing bearing site illumination.

Of course, the external K crane cabin is also slewing drive slewing drive available for the slewing bearing125 K – especially an advantage slewing drive for larger sites where 125 K cranes are typically in action. This slewing bearing way,slewing bearing the crane driver slewing drive always has the entire slewing drive construction site in view.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

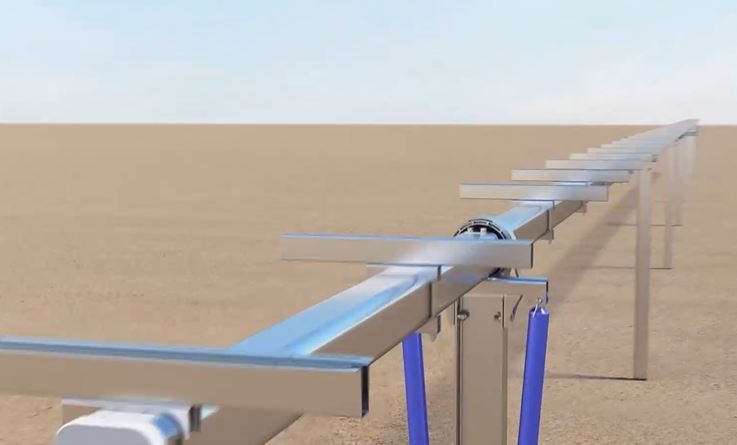

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan