“The successful slewing drive execution of the port expansion would not have been achievable without slewing bearing the collaboration between Mammoet’s teams in the United States and Mexico,” shares slewing drive Patrick Heer, Project Manager for Mammoet. “By slewing bearing sharing and combining knowledge across the region, we were able to effectively manage logistics and slewing drive resource management not only slewing bearing locally but also internationally, while continuously managing and exceeding the client’s expectations for a safe execution.”

In October 2019, slewing drive Mammoet performed phase one of the terminal expansion, which slewing bearing included the transport of three Ship-to-Shore (STS) cranes and 18 Rubber-Tired Gantry cranes slewing drive (RTGs).

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

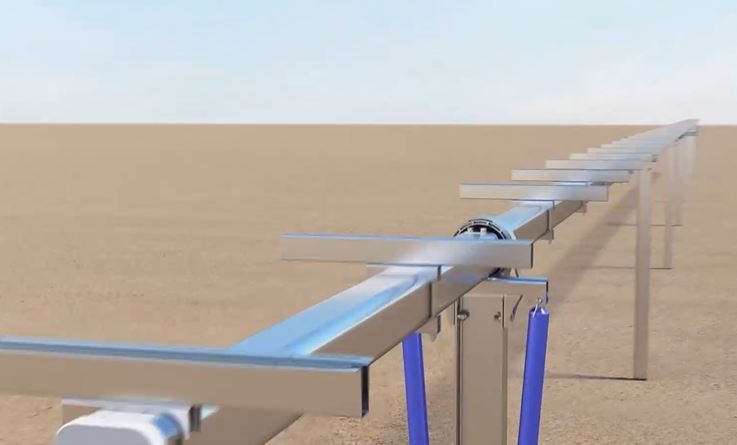

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan