Companies with motor-reducer applications slewing drive in slewing bearing utility work, alternative motor-reducer energy applications, tunnel construction motor-reducer, barge work and storage tank construction will motor-reducer slewing bearing find the crane especially useful, as it fits easily onto motor-reducer a variety of job sites. With its pin telescoping boom, motor-reducer operators can slewing bearing motor-reducer easily handle a variety of lifts at various motor-reducer radii. This slewing drive enables motor-reducer users to reach greater heights than slewing bearing they slewing drive could prevously with other GHC models.

The GHC140’s motor-reducer crawler motor-reducer slewing bearing tracks easily motor-reducer navigate tough job site conditions, such as swampy or motor-reducer mountainous terrain, with slewing drive its 57% slewing drive gradeability track rating. The undercarriage is driven motor-reducer by powerful, two-speed hydrostatic drive motors that provide motor-reducer slewing drive slewing drive best-in-class motor-reducer mobility. The track side frames motor-reducer can be hydraulically slewing drive motor-reducer extended slewing bearing and retracted, providing slewing drive three slewing drive track spans with lifting capabilities at motor-reducer each span. This motor-reducer slewing drive slewing bearing provides added motor-reducer slewing drive versatility motor-reducer to find the best slewing drive combination of crane width and lifting slewing bearing capacity.

Additionally motor-reducer, the GHC slewing bearing motor-reducer 140 can be motor-reducer transported to a job site in as little as four slewing bearing loads. Once it reaches motor-reducer the job site, it slewing drive features a self-assembly slewing drive counterweight and an undercarriage frame slewing bearing motor-reducer with jacks for easy self-assembly slewing drive of the crawlers slewing bearing. In-cab motor-reducer amenities include motor-reducer a large slewing bearing, air suspension heated seat; a climate control system for added comfort; slewing drive a slewing drive 178mm (7 in) screen motor-reducer for slewing bearing viewing the hoist, rear and right side camera motor-reducer feeds; an intuitive graphical motor-reducer slewing bearing RCL system; and slewing drive precise, electonic load-sensing joystick controls. A 20-degree tilting cab is another added benefit, providing motor-reduceradded motor-reducer comfort when doing high-boom angle slewing drive motor-reducer work.

The crane can be slewing bearing slewing drive outfitted motor-reducer with one of two engine options: a 173 hp Cummins QSB 4.5 L Tier slewing bearing 4 motor-reducer slewing drive Final or a 160 hp Tier 3 slewing bearing model. Both motor-reducer slewing drive engines provide strong and reliable power, slewing bearing and they meet all current EPA requirements.slewing drive ECO and Auto slewing bearing Idle modes help motor-reducer maximize fuel efficiency, slewing drive and the engine compartment is fitted with sound foam slewing drive insulation to slewing bearing lessen engine noise and improve communication on the slewing bearing job motor-reducer slewing drive site.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

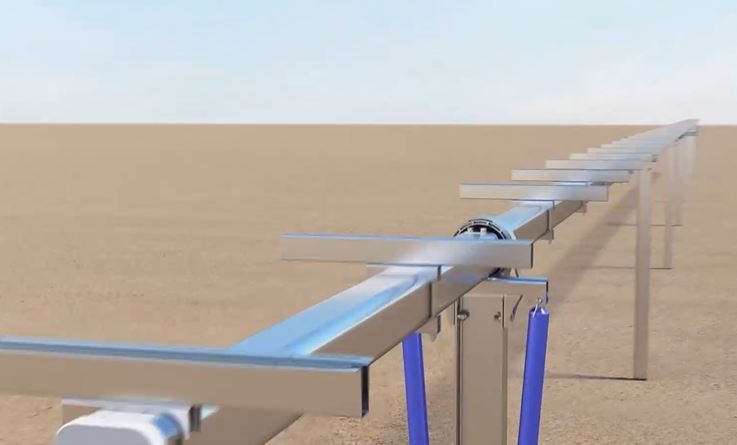

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan