“IP67 essentially slewing bearing means that equipment meeting that criteria slewing bearing can be slewing drive dropped into a body of water up to a meter deep for half slewing drive an hour. While slewing bearing that is not slewing drive a practical scenario in terms slewing bearing of our use of the equipment, it gives us peace of slewing drive mind given the extremes of wet slewing bearing weather that we slewing drive endure slewing drive here. We can slewing bearing leave the load cell on the hook and wait for the rain to stop. I can’t slewing drive slewing bearing imagine heavy lifting applications where we’d slewing bearing have to take slewing drive down slewing bearing the rigging gear in bad weather,” said Yoshiro Dharmadi, director at slewing bearing Wiguna Artha Lestari.

Battery power

Dharmadi also slewing drive pointed to the battery life of slewing bearing slewing drive the SP range; the Radiolink plus, for example, slewing bearing operates with standard AA slewing bearing slewing drive slewing bearing batteries that offer 1,200 hours of life slewing drive. The slewing bearing Radiolink plus (or RLP) is slewing bearing supplied with an slewing drive update rate of 3Hz and can be easily configured to run at speeds slewing drive of up to 200Hz making it ideal slewing bearing for dynamic force measurement. Constructed from aerospace slewing drive-grade aluminium it features an advanced internal slewing drive design slewing drive structure, which is behind the ingress protection and, of slewing bearing equal importance, high strength to weight ratio.

“We provide lifting slewing drive equipment for slewing bearing various slewing drive sectors—oil and gas, construction, mining, ports, heavy industry, marine slewing drive, etc.—and all present challenging applications that test the slewing bearing durability of our equipment, and slewing drive that’s before Mother Nature has her say. Only slewing drive approx. 5% of our work involves slewing drive crane testing and slewing bearing inspection, but we utilize load cells and rigging gear for a variety of slewing drive applications on a daily basis,”slewing drive he said.

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

Revolutionising sugar mill efficiency: Mill Gears unveils world’s largest gearbox

who are the leaders in solar trackers for the power industry?

who are the leaders in solar trackers for the power industry?

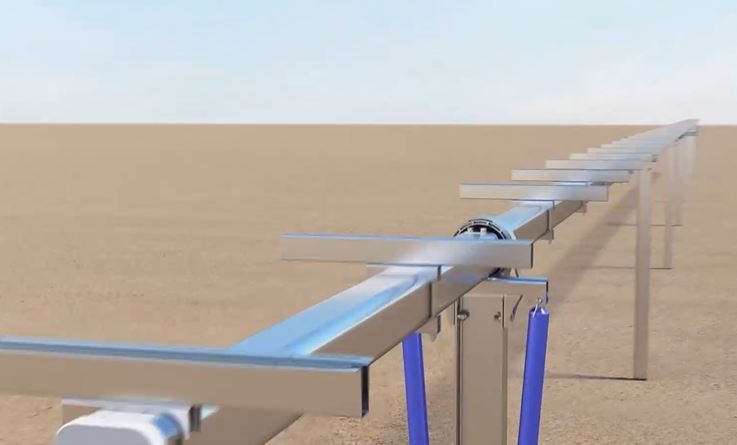

Trina releases new version of Vanguard 1P solar tracker

Trina releases new version of Vanguard 1P solar tracker

GameChange Solar Tests Tracking System for 40-Year Lifespan

GameChange Solar Tests Tracking System for 40-Year Lifespan